Release time:2023-08-30

choiceInjection moldingWhat should the manufacturer consider? Injection molding products are used in many fields of life, and there are many manufacturers engaged in injection molding in the market. Among the many injection molding manufacturers, which one do you choose? This problem is the concern of many customers, so it is very important to understand the factors that need to be considered when selecting a manufacturer for injection molding processing.

Factors to be considered when selecting a suitable injection molding manufacturer:

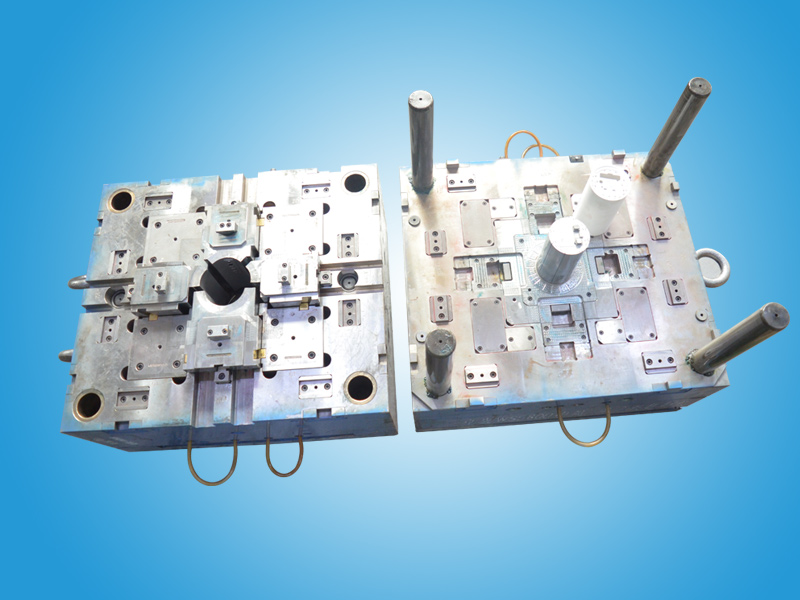

1. Injection molding equipment

In the process of selecting an injection molding manufacturer, one factor to be considered is the equipment used by the manufacturer, because the quality of injection molding equipment affects the quality of injection molding products. The quotation of injection molding manufacturers using better injection molding equipment may be more expensive, because the injection molding equipment purchased by the injection molding manufacturers is more expensive, and the injection molding cost needs to be considered. Of course, the factory can make a batch of samples first. Carefully observe the advantages and disadvantages of the product before considering the selection.

2. Delivery time

When selecting an injection molding manufacturer, we should also observe its delivery time. We all hope that we can get our own goods as much as possible. If the production capacity of the injection molding manufacturer is limited and cannot deliver on time, it will lead to a series of subsequent troubles. Therefore, we should choose an injection molding manufacturer that can complete the injection molding requirements within the specified time period. Therefore, the delivery time is an important factor that we need to consider when selecting an injection molding manufacturer.

3. After sales problems

In the process of determining the injection molding manufacturer, we should also pay attention to the problems after delivery. This is because if the transportation and after-sales of injection molding processing can be improved, it will save a lot of trouble. Especially when some injection molding parts need to be reworked, it will be very good if the manufacturer can quickly come up with a feasible plan.

Therefore, the injection molding manufacturer should first consider the injection molding equipment purchased by the factory, delivery time, after-sales transportation, etc. it is more important for the injection molding manufacturer to provide a complete set of corresponding solutions from proofing production to transportation after-sales.